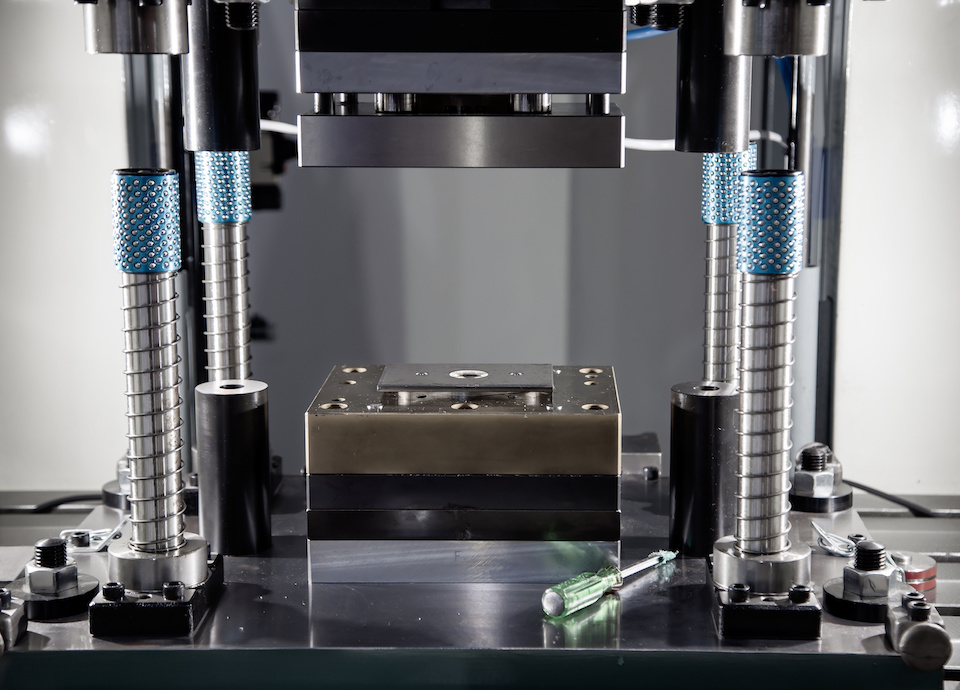

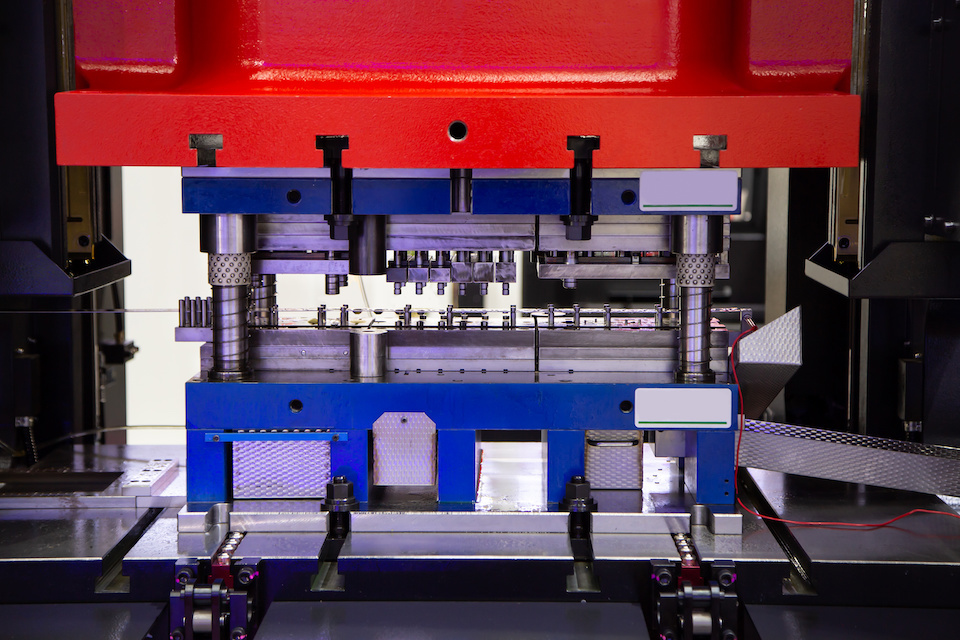

Prototyping

Prototype parts and assemblies for initial trials and proof of concept are often required in the initial stages of a project. Canterbury Tools can provide vast experience and cost-effective solutions in this area.

Using in-house finite element analysis software, we can provide feedback and advice on suitability for the manufacture of concept parts at an early stage before any material cutting occurs.

We often work closely with customers to modify components to improve feasibility or process cost in production.